Advances in management practices, production systems, the control and eradication of major diseases, continued genetic development, and the use of a wide variety of biotechnologies have highlighted pig production at a global scale to levels that seemed unattainable.

![]() However, several obstacles remain (e.g., attaining maximum production efficiency, seasonal diseases, and reducing the effects of mycotoxins on pigs).

However, several obstacles remain (e.g., attaining maximum production efficiency, seasonal diseases, and reducing the effects of mycotoxins on pigs).

Studies conducted by FAO estimate that 300 or more existing mycotoxins contaminate 25% of the world’s grain reserves.

Studies conducted by FAO estimate that 300 or more existing mycotoxins contaminate 25% of the world’s grain reserves.

Conservationist planting practices, such as direct seeding, have generated a notable increase in the contamination of plants during their development and this has greatly aggravated in the humid climate of Argentina, where it is common to find very high levels of different mycotoxins produced mainly by fungi from the genus Fusarium and Aspergillus.

In this paper, the experience of testing Minazel Plus® at site 1 of four intensive pig breeding farms, two of them in the Province of Buenos Aires (San Andrés de Giles and Salto), one in Entre Ríos (Gilbert), and another in Córdoba (Monte Maíz).

In this paper, the experience of testing Minazel Plus® at site 1 of four intensive pig breeding farms, two of them in the Province of Buenos Aires (San Andrés de Giles and Salto), one in Entre Ríos (Gilbert), and another in Córdoba (Monte Maíz).

⇰ The results of this trial include the reproductive data obtained for the last 4 years where the results of the farms before and after the use of the Minazel Plus® are compared.

USE AND RESULTS OF MINAZEL PLUS® AT CAFFARO FARM

The first trial was carried out at CAFFARO Farm, a breeding pig farm with 280 sows located at Salto.

SERVICE/GESTATION STAGE

SERVICE/GESTATION STAGE

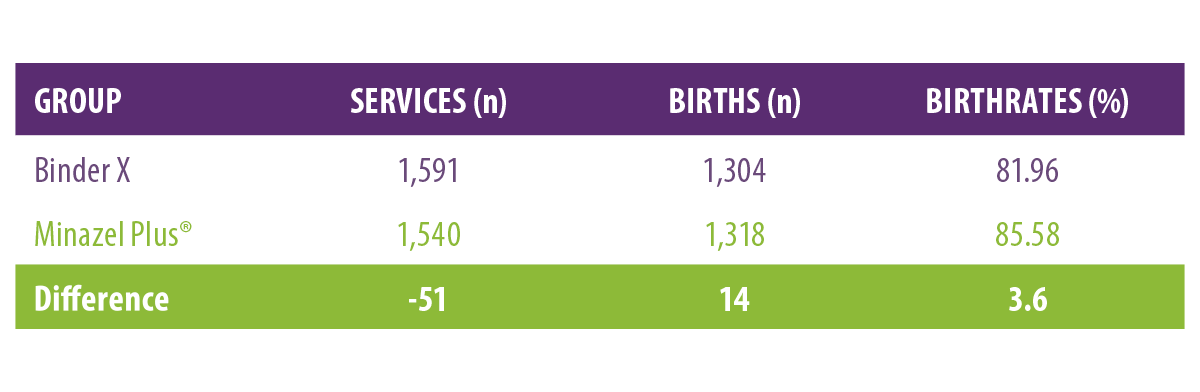

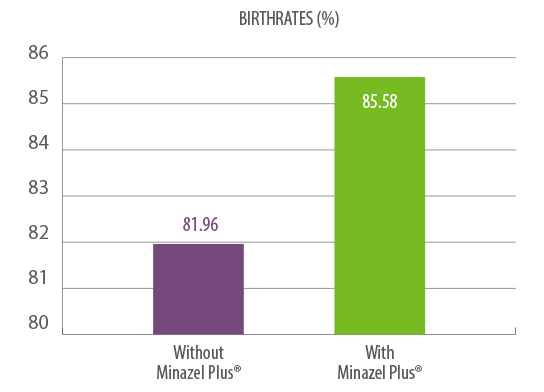

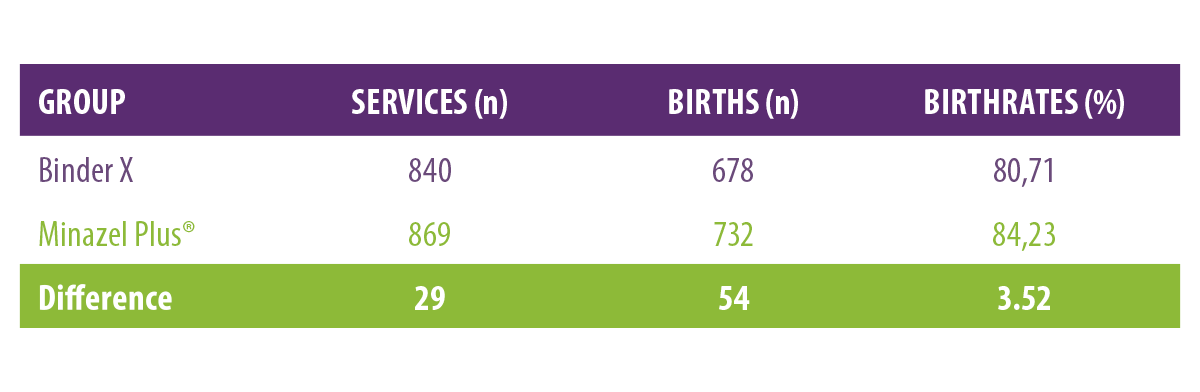

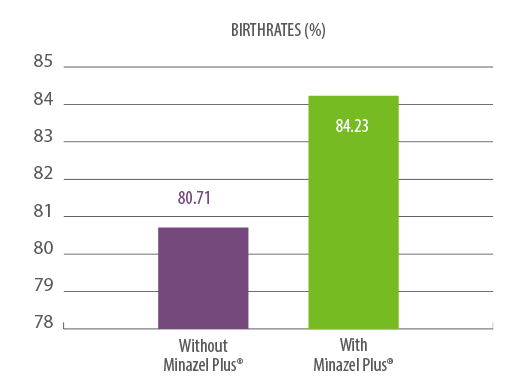

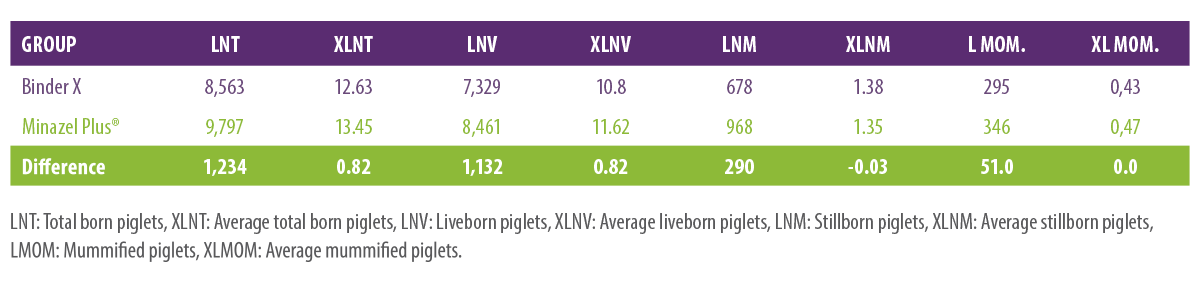

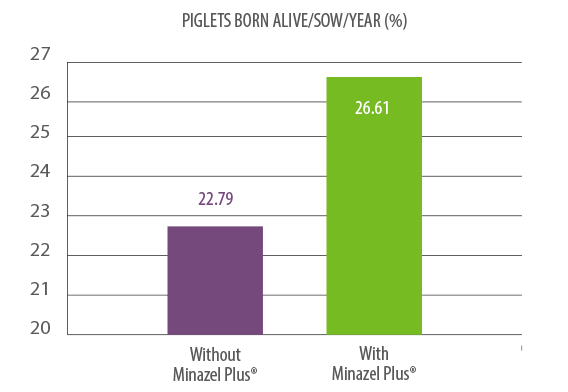

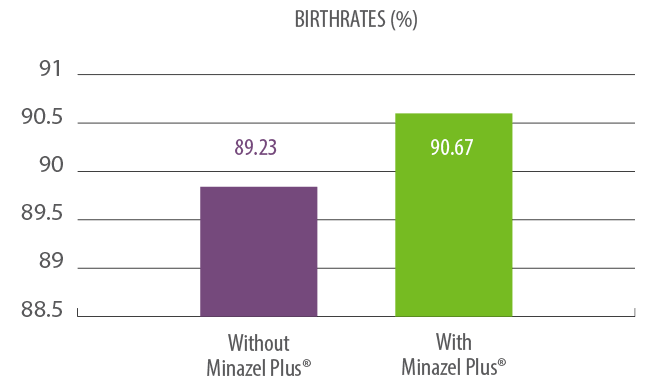

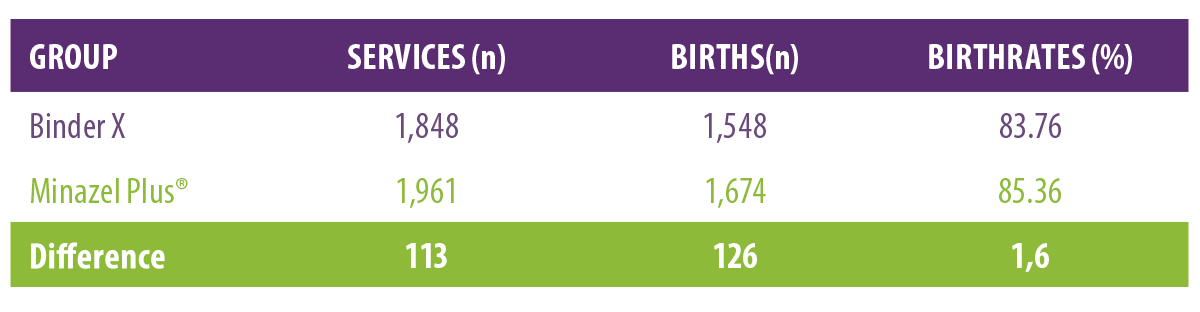

Table 1 and Figure 1 show data on the service/gestation stage for the period from May 2018 to April 2020, when a broad-spectrum binder was used, and for the period from May 2020 to April 2022, when Minazel Plus® was used:

Table 1. Comparison of the data on service, births and birthrates registered at CAFFARO Farm before and after using Minazel Plus®.

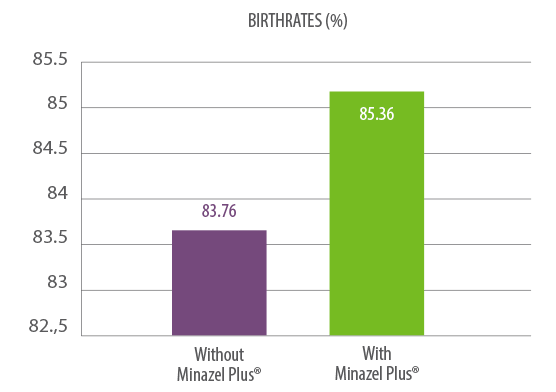

F¡igure 1. Comparison of the birthrates registered at CAFFARO Farm before and after using Minazel Plus®.

FARROWING/LACTATION STAGE

FARROWING/LACTATION STAGE

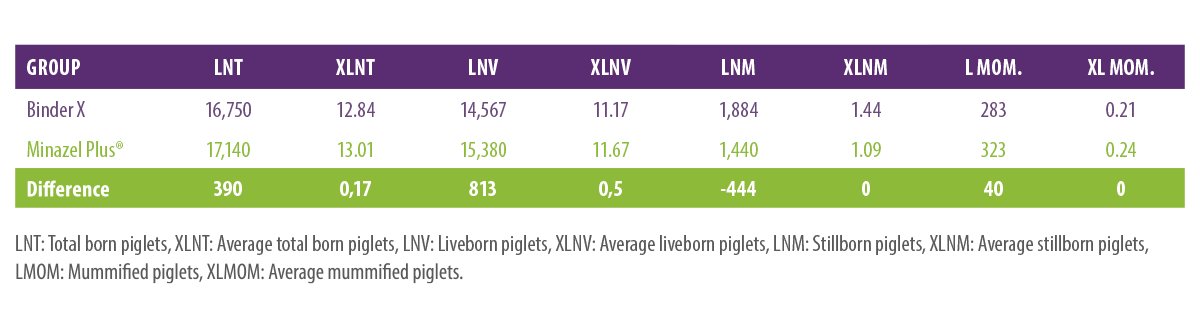

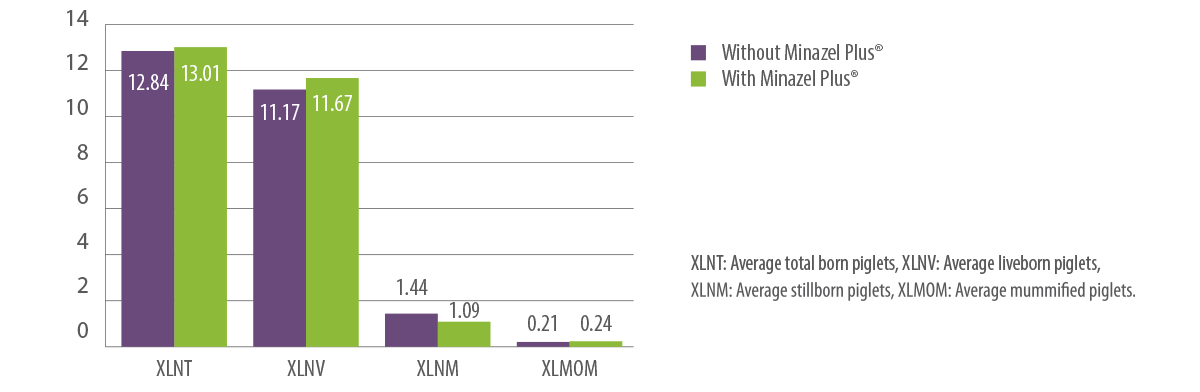

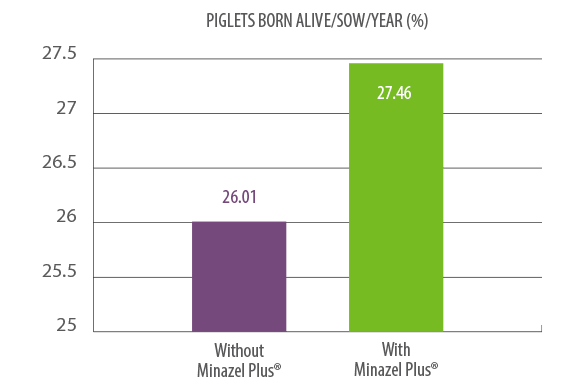

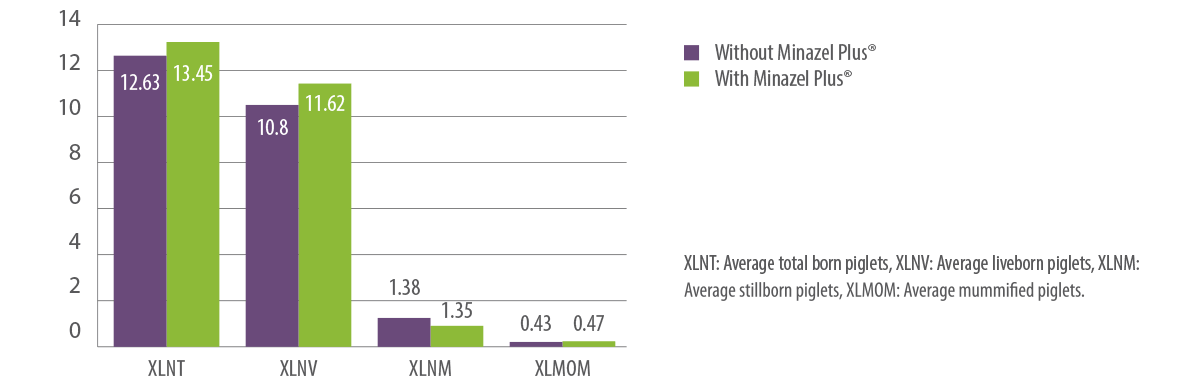

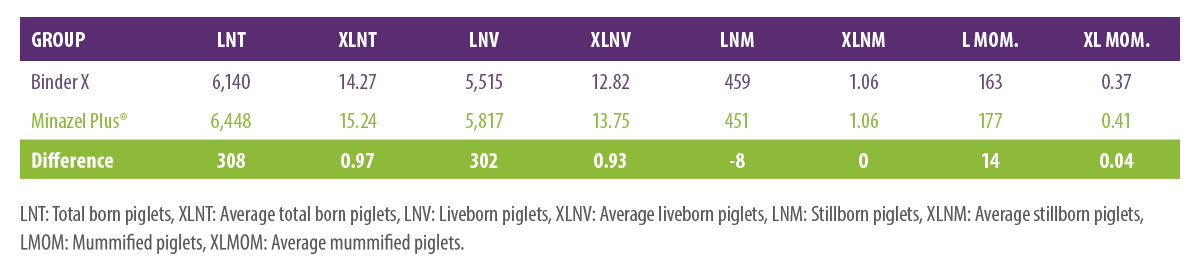

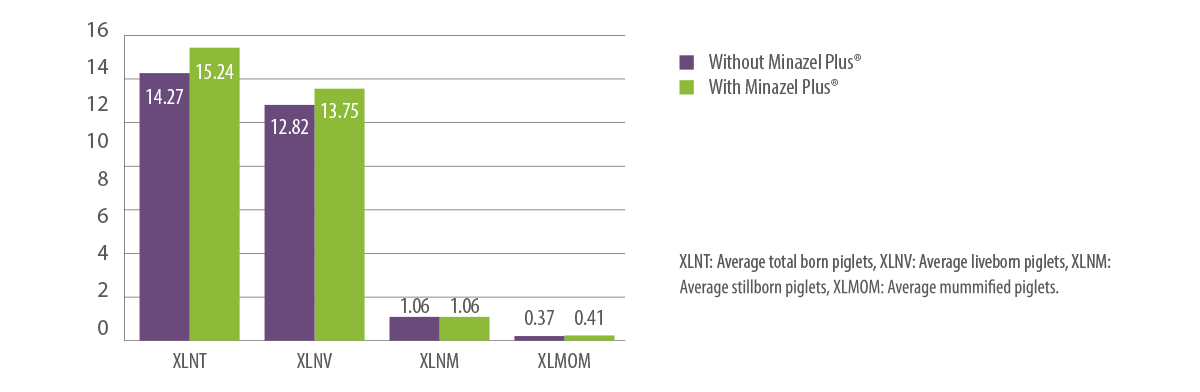

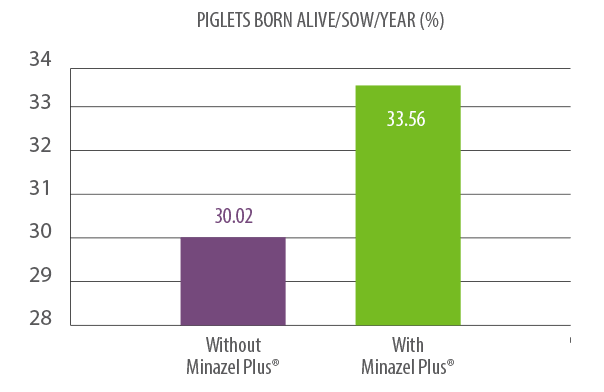

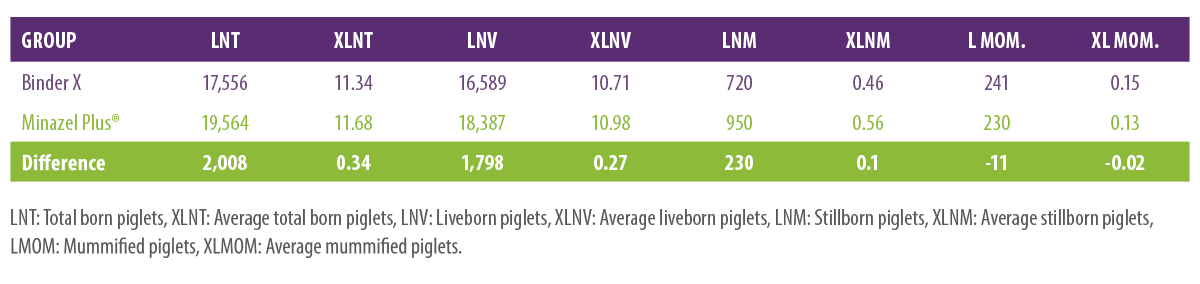

Table 2 and Figure 2 show the results of the farrowing/ lactation stage from May 2018 to April 2020, when a broad-spectrum binder was used, and from May 2020 to April 2022, when Minazel Plus® was used:

Table 2. Comparison of the data on the number of total, liveborn, stillborn and mummified piglets registered at CAFFARO Farm before and after using Minazel Plus®.

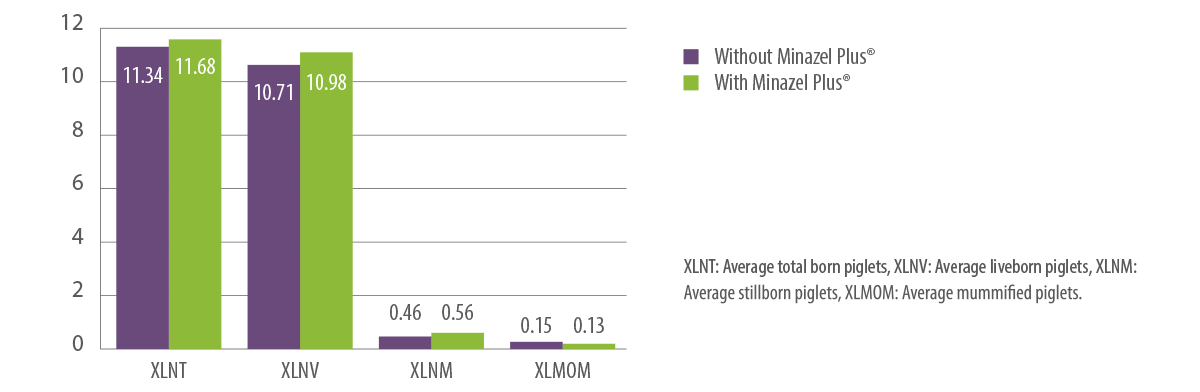

Figure 2. Comparison of the data on average number of total, liveborn, stillborn and mummified piglets registered at CAFFARO Farm before and after using Minazel Plus®.

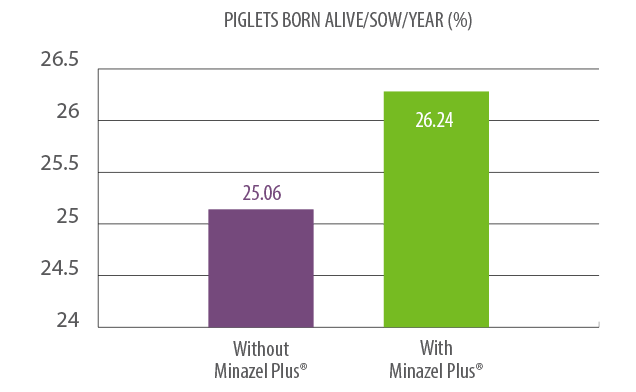

Figure 3. Comparison of the data on piglets born alive per sow per year registered at CAFFARO Farm before and after using Minazel Plus®.

USE AND RESULTS OF MINAZEL PLUS® AT PARISI FARM

The second trial was carried out at PARISI Farm, a breeding pig farm with 160 sows located at San Andrés de Giles.

SERVICE/GESTATION STAGE

SERVICE/GESTATION STAGE

Table 3 and Figure 4 show data on the service and gestation stage for the period from May 2018 to April 2020, when a broad-spectrum binder was used, and for the period from May 2020 to April 2022, when Minazel Plus® was used:

Table 3. Comparison of the data on the service, births and birthrates registered at PARISI Farm before and after using Minazel Plus®.

Figure 4. Comparison of the birthrates registered at PARISI Farm before and after using Minazel Plus®.

FARROWING/LACTATION STAGE

FARROWING/LACTATION STAGE

Table 4 and Figure 5 show the results of the farrowing/ lactation stage from May 2018 to April 2020, when a broad-spectrum binder was used, and from May 2020 to April 2022, when Minazel Plus® was used:

Table 4. Comparison of the data on the number of total, liveborn, stillborn and mummified piglets registered at PARISI Farm before and after using Minazel Plus®.

Figure 5. Comparison of the data on average number of total, liveborn, stillborn and mummified piglets registered at PARISI Farm before and after using Minazel Plus®.

Figure 6. Comparison of the data on piglets born alive per sow per year registered at PARISI Farm before and after using Minazel Plus®.

USE AND RESULTS OF MINAZEL PLUS® AT THORN FARM

The third trial was carried out at THORN Farm, a breeding pig farm with 160 sows located at Gilbert (Entre Rios).

SERVICE/GESTATION STAGE

SERVICE/GESTATION STAGE

Table 5 and Figure 7 show data on the service/gestation stage for the period from November 2018 to November 2020, when a broad-spectrum binder was used, and for the period from December 2020 to December 2022, when Minazel Plus® was used:

Table 5. Comparison of the data on the service, births and birthrates registered at THORN Farm before and after using Minazel Plus®.

FFigure 7. Comparison of the birthrates registered at THORN Farm before and after using Minazel Plus®.

FARROWING/LACTATION STAGE

FARROWING/LACTATION STAGE

Table 6 and Figure 8 show the results of the farrowing/ lactation stage from November 2018 to November 2020, when a broad-spectrum binder was used, and from November 2020 to November 2022, when Minazel Plus® was used:

Table 6. Comparison of the data on the number of total, liveborn, stillborn and mummified piglets registered at THORN Farm before and after using Minazel Plus®.

Figure 8. Comparison of the data on average number of total, liveborn, stillborn and mummified piglets registered at THORN Farm before and after using Minazel Plus®.

Figure 9. Comparison of the data on piglets born alive per sow per year registered at THORN Farm before and after using Minazel Plus®.

USE AND RESULTS OF MINAZEL PLUS® AT BERNAY FARM

The last trial was carried out at BERNAY Farm, a breeding pig farm with 330/350 sows located at Monte Maíz (Córdoba).

SERVICE/GESTATION STAGE

SERVICE/GESTATION STAGE

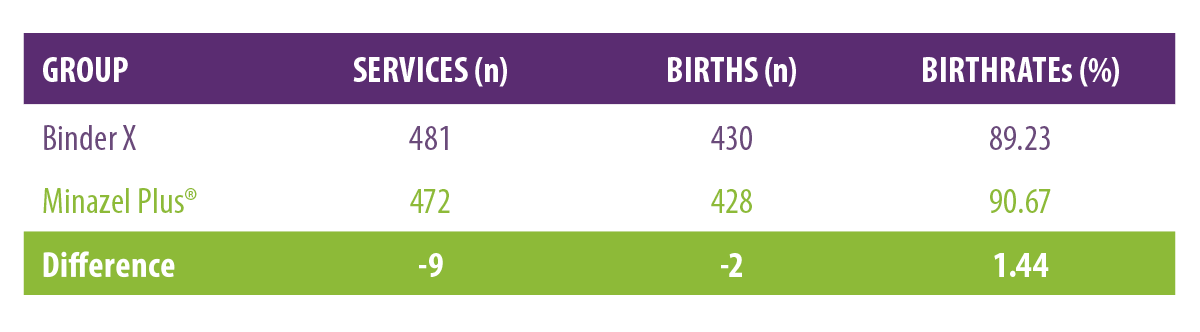

Table 7 and Figure 10 show data on the service/gestation stage for the period from May 2018 to April 2020, when a broad-spectrum binder was used, and for the period from May 2020 to April 2022, when Minazel Plus® was used:

Table 7. Comparison of the data on the service, births and birthrates registered at BERNAY Farm before and after using Minazel Plus®.

Figure 10 . Comparison of the birthrates registered at BERNAY Farm before and after using Minazel Plus®.

FARROWING/LACTATION STAGE

FARROWING/LACTATION STAGE

Table 8 and Figure 11 show the results of the farrowing/ lactation stage from May 2018 to April 2020, when a broad-spectrum binder was used, and from May 2020 to April 2022, when Minazel Plus® was used:

Table 8. Comparison of the data on the number of total, liveborn, stillborn and mummified piglets registered at BERNAY Farm before and after using Minazel Plus®.

Figure 11. Comparison of the data on average number of total, liveborn, stillborn and mummified piglets registered at BERNAY Farm before and after using Minazel Plus®.

Figure 12. Comparison of the data on piglets born alive per sow per year registered at BERNAY Farm before and after using Minazel Plus®.

ECONOMIC ANALYSIS OF THE RESULTS OF THE USE OF MINAZEL PLUS®

![]() At the end of the trial, an economic analysis of each farm concerning the use of Minazel Plus® on each farm was carried out as shown below.

At the end of the trial, an economic analysis of each farm concerning the use of Minazel Plus® on each farm was carried out as shown below.

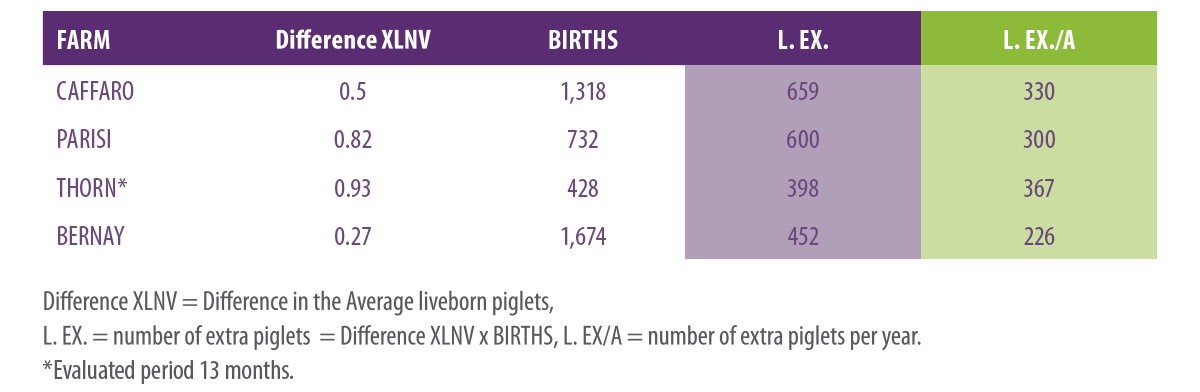

To calculate the increase in the number of liveborn piglets associated with the use of Minazel Plus®, the difference in the average number of extra liveborn piglets (Difference XLNV) was multiplied by the number of births (BIRTHS) that occurred during the treatment period with Minazel Plus®, which represents the number of extra piglets (L. EX.) obtained during the evaluated period in each farm (2 years) (Table 9).

Table 9. Number of extra piglets obtained during the treatment period with Minazel Plus® (2 years) and per year.

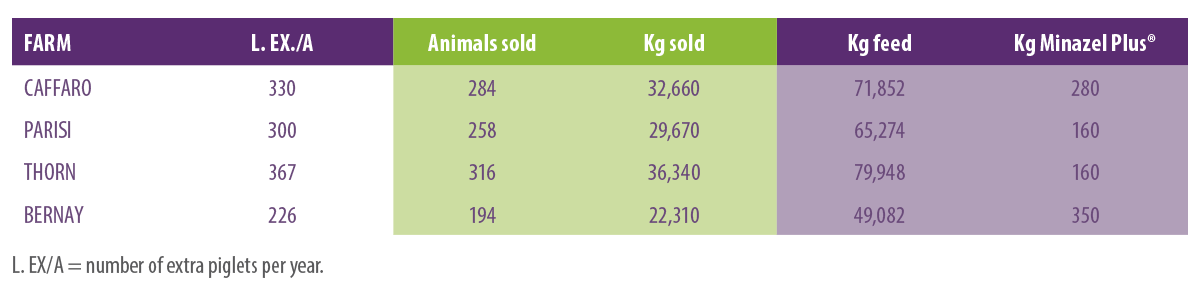

Next, the profits were calculated based on a total mortality (born/sold) of 14%, a slaughter weight of 115 kg, a born/ sold feed conversion of 2.2 kg of feed/kg produced, and an average feed cost of US$60/kg (Table 10).

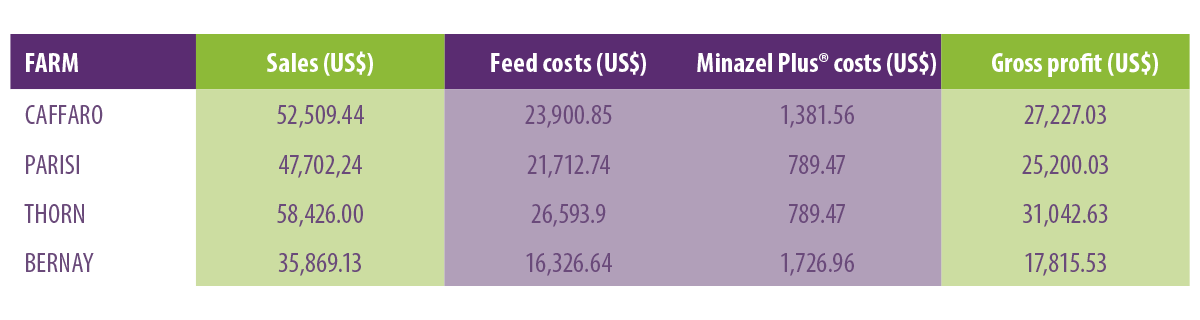

Table 11 shows the profits for each farm during the treatment period with Minazel Plus®.

Tabla 10. Resumen de la cantidad de animales y kilogramos vendidos y de la cantidad de pienso y Minazel Plus® consumidos durante el periodo de tratamiento de 2 años.

Table 11. Summary of the profit margin during the 2-year treatment period with Minazel Plus®.

![]() CONCLUSION

CONCLUSION

These four farms are located in 3 different Argentinian provinces, all of them in soybean/corn agricultural areas where the climate is quite similar and with similar sanitary realities. As for genetics, they are the same and all have a gilt replacement program based on liquid genetics from the same genetics company.

The supply of raw materials for feed relies on procurement in the first three farms, whereas the fourth (Cordoba) produces its own corn. As for the supply of starter and nucleus feeds, all of them come from different companies. In addition, the four farms differ significantly in terms of structure and personnel.

|

Despite the similarities and differences between these farms, in all cases, the use of Minazel Plus® resulted in productive differences with high profitability. Considering that each sow consumes 1 kg of Minazel Plus®/year, an amount that can be increased as needed, the result is likely to be linear.

In this case, it was decided to use the product in all phases at a single dose of 1kg/Tn, regardless of the raw material mycotoxin analysis that is carried out regularly. |

Micotoxicosis prevention

Micotoxicosis prevention