- ⇰ The sampling may be carried out directly on the truck, by continuous flow or in the pile of sacks.

- ⇰ In this chart, instructions for taking samples from different stages of feed production are shown.

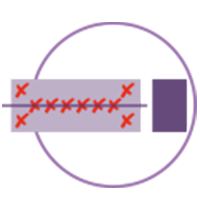

TRUCK

QUANTITY

10 to 20 tons of raw material 6 to 8 kg of sample

20 to 50 tons of raw material 10 kg of sample

POINT

Sample the front, rear right and left points, and then continue in the centre of the truck with a gap of one meter.

FINAL SAMPLE

The spear should be inserted from top to bottom at the marked locations for the truck.

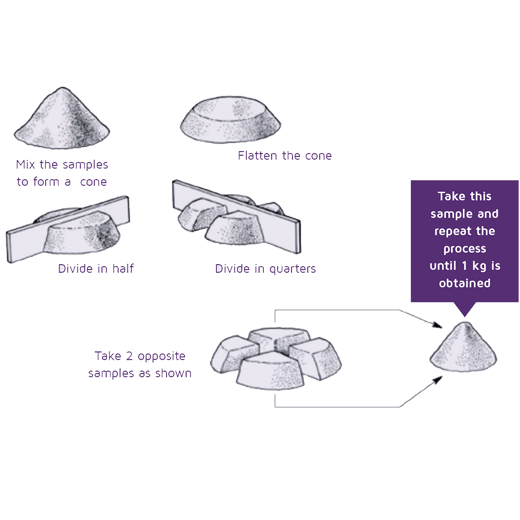

The samples should be taken, pulled and then mixed, homogenized and quartered to get 1 kg of total sample.

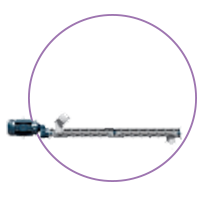

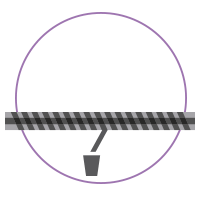

CONTINUOUS FLOW

QUANTITY

POINT

Make a hole in the screw conveyor, put a tube at an angle of 45° taking into account the flow direction of the raw material in conveyor

FINAL SAMPLE

All samples should be mixed, homogenized and quartered to get 1 kg of representative sample.

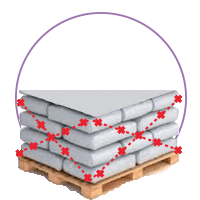

PILE OF SACKS

QUANTITY

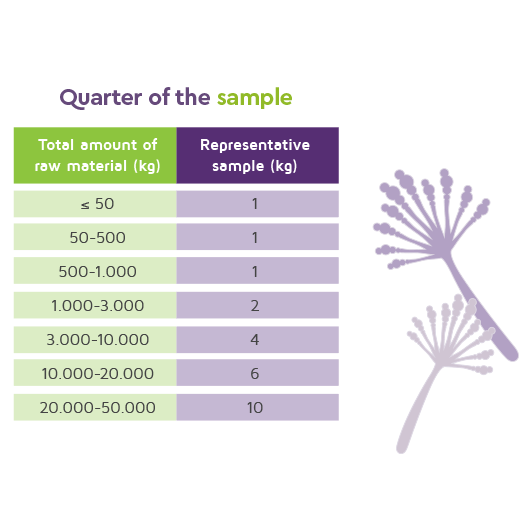

Refer to Quarter of the sample Table on the right

POINT

Sample the visible faces of the pile, it must be done in the form of X, trying to take a sample from each line of bags

FINAL SAMPLE

The spear should be inserted in the demarcated points, the sample is taken and removed.

All samples should be mixed, homogenized and quartered to get 1 kg of representative sample

PATENT CO, DOO., Vlade Ćetkovića 1A, 24 211, Mišićevo, Serbia

Micotoxicosis prevention

Micotoxicosis prevention