Mycotoxins are secondary metabolites of molds that have adverse effects on animal health.

They are a heterogeneous group, which results in a high variability of toxic effects.

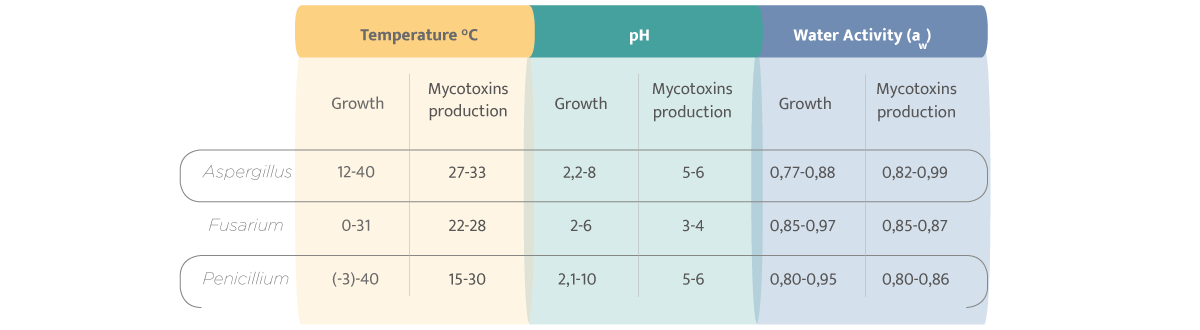

Mycotoxins are produced by various species of molds, among which the most common belong to the Aspergillus, Penicillium, Claviceps and Fusarium genera.

There are several microbial groups capable of growing in meat and meat products, due to their ubiquity and tolerance to diverse environmental conditions.

Hygiene and Food Safety, Faculty of Veterinary Medicine.

Meat and Meat Products Institute. Cáceres, University of Extremadura, Spain

Microbial Growth Factors in Meat and Meat Products

Factors determining what type of microorganism proliferates in meat and meat products are determined by physical and chemical characteristics of the food, such as:

- pH

- Water activity (aw)

- NaCl concentration

- Storage temperature

- Presence or absence of oxygen, etc.

Molds and yeasts are dominant in lower aw feed, such as cured and ripened meat products.

Table 1. Conditions for growth and mycotoxins production required by the genera Aspergillus, Fusarium and Penicillium (Adapted from Sweeney and Dobson, 1998).

How mycotoxins reach meat?

Mycotoxins can reach meat and meat products in two ways:

- Through consumption of meat and meat products from animals which have consumed feed contaminated with mycotoxins

- Through the growth of toxigenic molds on the surface of cured and ripened meat products

Mycotoxin Contamination in Animal Feed

Also, mycotoxins ingested by animals can be accumulated in different organs and tissues of such animals, which may be very dangerous for consumers, since mycotoxins cannot be destroyed using the usual food processing techniques.Due to molds ubiquity, the effective controls of the danger of presence of mycotoxins in feed and silage in storages should be established in environmental conditions impeding their development.

Table 2. Approximate values in mg/kg (ppm) for feed with a moisture content of 12%. (Recommendation 2006/576 / EC and Regulation 574/2011 / EC)

Limits

European Food Safety Authorities have set maximum limits of these contaminants in products intended for animal feed.

- Regulation 574/2011 (European Commission, 2011) sets maximum levels of Aflatoxin B1 and ergot, ergotamine producer (European Commission, 2011)

- Recommendation 2006/576 (European Commission, 2006b) establishes the maximum tolerated levels that the following mycotoxins: Ochratoxin A, Deoxynivalenol, Zearalenone and Fumonisins B1 and B2 should not exceed in feed with a moisture content of 12% (Table 2).

Growth of Molds on the Surface of Cured and Ripened Meat Products

Molds developed in the cured and ripened meat derivatives during their maturation can have both positive and negative effects regarding the quality and safety of the final product.

Beneficial Effects of Molds

The following are some of the most beneficial effects attributed to molds:As a consequence of this activity, there is an increase in the concentration of amino acids and free fatty acids, precursors of desirable volatile compounds in cured and ripened meat products.

Due to their production of enzymes such as catalase, molds constitute an antioxidant barrier.

In general, it relates to molds with reduced rancidity, which positively affects the sensory level.

Negative Effects of Molds

The following are negative effects associated with the growth of molds on the ham surface:- Molds can cause defects or sensory alterations

- Molds can produce mycotoxins, which, from the point of view of food security, is more alarming (Núñez et al 2007, Rodríguez et al., 2012)

The maximum levels have been established for the following:

- Aflatoxins (Ministry of Health and Consumer Affairs 2001; European Commission 2010a)

- Ochratoxin A (OTA) (Ministry of Health and Consumer Affairs 2003; European Commission 2010b) (*)

- Patulin (Ministry of Health and Consumer Affairs 2004; European Commission 2006)

- and Fusarium toxins (European Commission 2005, European Commission 2007)

Most of the molds isolated from sausages and cured ham belong to the genera Penicillium and Aspergillus, which are potentially toxigenic (Núñez et al 1996).

In addition, several toxigenic species belonging to these two genera produce mycotoxins when growing on the surface of cured ham (Nunez et al 2007;. Rodríguez et al 2012.).

Mold Control Methods in Cured and Ripened Meat Products

Because of the danger posed by the production of mycotoxins, it is necessary to establish viable strategies to avoid its synthesis during the processing of cured and ripened meat products.There are different methods of control of these processes, among which we can mention:

Physical and chemical methods

2. Chemical methods (controlled atmospheres, organic acids, essential oils or hydrogen peroxide)

- Many of these treatments are not applicable during the processing of cured and ripened meat products, as they would impede the correct development of such maturation process

- Large volume of drying rooms and difficult handling of a large number of pieces make physical treatments difficult to be applied

- Although various chemical preservatives, such as sorbic acid and propionic acid, can be used to control the growth of molds, they are not completely effective.

Use of non-toxigenic strains

Variations in the maturation conditions of these products could prevent the development of fungal population, but it may also reduce the sensory quality of the final product.

The industry has to find alternative strategies to control this danger.

Conclusions

The ability of these microorganisms to implant themselves and to exert their effect is better if they are in the form of strains isolated from cured and ripened products, given their power to adapt to those particular ecological conditions.

The use of these microorganisms as protective crops does not suppose a rupture with the usual microbiota in these products.

Lactic acid bacteria, yeasts and molds producing antifungal proteins are one of the most important microorganisms present in this type of products able to inhibit the development of toxigenic molds or the formation of mycotoxins.Acknowledgements This work was funded by the Ministry of Economy and Competitiveness, Government of Extremadura and FEDER (AGL2013-45729-P, GR15108).

Micotoxicosis prevention

Micotoxicosis prevention