The quality of poultry feed is an important prerequisite to achieve optimal

production results, and the preservation of the health status of animals,

especially in intensive livestock production, hence it is necessary to control both

raw materials and finished feed mixtures.

The presence of fungi (moulds) in food for

animals is a natural phenomenon, not an exception.

Sources of contamination of poultry feed with fungi and resulting mycotoxins vary, starting with raw materials (e.g. corn as the most common component) during harvest and transport, during storage of raw materials and finished products, as well as in the production process and manipulation of poultry feed.

1Department of Animal Husbandry, Faculty of Agronomy, University of Kragujevac, Cacak, Serbia 2Institute of Zootechnic, Faculty of Agriculture, University of Belgrade, Belgrade (Serbia) 3Institute for food technology in Novi Sad (Serbia) 4Center of Small Grains, Kragujevac, (Serbia)

MINERAL ADSORBENTS

Mineral adsorbents are increasingly used in poultry production, especially in the nutrition of various types and categories of poultry, to control fungal contamination.Using different mineral adsorbents in poultry nutrition can prevent the losses due to mycotoxicosis. It can also prevent:

- Appearance of toxic residues in poultry products

- Improve production and reproductive ability of birds

- Contribute to improving the quality of poultry products

The use of mineral adsorbents in poultry feeds has application in neutralising the harmful effects of mycotoxins in buildings where poultry is reared.

Datas introduction

According to official data from global institutions such as the FAO, at least 99 countries in the world, which contain approximately 87% of the world population, have some kind of regulation for the content of mycotoxins in food for humans and/or animals.Worldwide interest in these problems is reflected in the vast number of scientific and professional papers published on mycotoxins since the discovery of aflatoxin B1 in the early 1960’s.

Given the ubiquitous nature of moulds, as well as the general impossibility to prevent mycotoxin contamination in foods feed materials, this topic is an integral part of modern livestock production.Although it is almost impossible to examine and measure the true impact of moulds and mycotoxins, the risks associated with the presence of mycotoxins is well researched and proven.

The increase in irregularity of meteorological conditions associated with global climate change has increased the problems of fungal contamination at harvest and the production of toxins.

Mycotoxins

Mycotoxins are toxic secondary metabolites of a large number of saprophytic organisms (moulds), which, proliferate in contaminated food infested with spores, conidia and/or fragments of mycelium.Fungal toxins entering the body of animals and humans via the gut cause intoxication, generally called mycotoxicosis.

Damage to livestock due to mycotoxicosis may be significant, and is manifested in the form of direct losses due to mortality of animals or, more commonly, caused indirectly due to falling production and reproductive performance (Ožegović, 1983).

A specific problem is the mycotoxin residues found in different quantities in edible organs and animal products, which enter the foodchain and may cause adverse effects in humans.

Mycotoxins properties

In chemical terms, mycotoxins represent a wide range of complex compounds with different functional groups and therefore different properties:

- Mycotoxins do not have sufficiently large molecules, and human and animal organisms do not produce antibodies against them and so remain permanently unprotected from their action

- There is no simple method for their identification

Most frequent mycotoxins in food

Common mycotoxins in foods include:

- Aflatoxins

- Ochratoxin

- Fusarium toxins (zearalenone, trichothecenes)

- Ergot alkaloids

- Sterigmatocistin

- Patulin

- Penicillanic acid

- Rubratoksins

- Sporodezmins

Zeolites

Semmens (1983) state that zeolites, as mineral adsorbents, in accordance of their structure, are part of the alumina silicates group (SlO4 and AlO4), where the tetrahedral structure (TO4) is the basic unit.Zeolite structure

Tetrahedrons may contain various bonds, giving the zeolite structure many channels and cavities.

TThe channel system may be One-dimensional (unconnected parallel channels) Two-dimensional (channels connected in one plane) and Three-dimensional.

The diffusion rate of adsorption and ion exchange are functions of the spatial channels distribution.

Every mineral is characterised by the channel opening size, so zeolites selectively retain or lose molecules depending on their dimensions.

Negative charge

The negative charge of the threedimensional network, which is conditioned with tetrahedral coordination, is characteristic of all the zeolites, with respective isostructural substitution of Sl4+ ions with Al3+ ions.The surplus negative charge is compensated for by univalent and/or divalent cations which are located in the channels and cavities.

The presented ions do not enter the zeolite tetrahedron network and, with the ion exchange reaction, they can be replaced by cations of other metals.

The cation exchange capacity of zeolites is a function of silicon substitution with aluminium in the tetrahedron network.

More alkali cations are required to compensate for the negative charge of elementary cells if the degree of substitution is higher.

The cation exchange capacity for natural zeolite is dependent on the dimensions of the channels, ionic shape and size, the charge density and ionic valency from the electrolyte composition and is in the range of 200-300 mEq/100g in zeolites (Dixon y Weed, 1989).

Clinoptilolite supplementation in feed

Boyer (2000) states that clinoptilolite supplementation in animal feed leds to a significant increase in feed efficiency as well as reducing the potential of intestinal diseases (diarrhoea), and the toxic effects of surplus ammonium ions.Some researchers explain this as the clinoptilolite preference for large ions, such as NH4+, so it serves as a reservoir for ammonia. Some natural zeolites adsorb mycotoxins from feedstuffs and offer some protection from their toxic affects during digestion.

Mixing process

The process of mixing is an important phase in the production of premixes and feeds, in order to attain uniformity in the basic matrix (carrier) distribution of the components so that each consumed amount of feed contains the required amount of nutrients (Filipović et al., 1993), including toxin binders.Spoilage of animal feed means deviation from the normal quality in terms of changes of organoleptic characteristics, nutritional value and/ or hygiene of food stuffs (Šefer et al., 1997).

Feed contamination with fungi causes poorer productive performance, increased metabolic disorders and diseases, and can eventually cause death. As a result, the presence of moulds in animal feed is an important criterion in evaluation of the quality of an animal feed.

Feed samples

In Serbian conditions, feed samples commonly contain zearalenone, ochratoxin A, trichothecenes (T-2, DAS) and aflatoxins.Research by Bočarov-Stančić et al. (2000) and Jajić et al. (2010) showed that in years with good climatic conditions, between 20 and 25% of cereals were contaminated with mould and mycotoxins. Rajić and Ožegović (1990) suggested a set of measures for the prevention and control of moulds in corn, namely:

- The selection of corn resistant to mould

- Seeding early varieties

- Prevention of grain breakage

- Artificial grain drying

- Hygienic cleaning of the grain hoppers

- Grain aeration

- Tighter control measures for moisture

- Treating grain with propionic acid or a mixture of organic acids

Adsorbent in Poultry production

In intensive poultry production adsorbents most often used to neutralise the harmful effects of mycotoxins achieve this by bonding.Adsorption is one of the most important and common methods in preventing mycotoxicosis.

Some of the adsorbents used include:

- Activated charcoal

- Hydrated sodium-aluminosilicates calcium (HSCAS)

- Bentonite

- Clay soil

- Various aluminosilicates or zeolites (Adamović et al., 2003; Resanović et al., 2004)

Supplementing zeolites

Supplementing zeolites at a rate of 0.5% in poultry feed under field conditions has achieved good results in the prevention of mycotoxins.Further research on the different categories of poultry showed that zeolites can be used in amounts of 0.2% of the feed to effectively prevent the harmful effects of mycotoxicosis (Radović et al., 2000), which confirmed the previous results obtained in vitro.

Adding 0.5% of the commercial zeolite ‘Min-a-Zel’(MZ) in feed for laying hens contaminated with T-2 toxin (2 mg/kg in corn and 1.2 mg/kg in sunflower pellet) had a positive impact on increasing laying capacity and mitigated the negative effects of T-2 mycotoxicosis.

The research using MINAZEL in hens diets, supplemented at levels of 0, 0.2, 0.3 and 0.5%, confirmed that the best performance was with 0.5% MINAZEL, giving increased laying, higher egg weight, better feed intakes, less feed consumption per egg, and improved FCR (Radović, 1997; Radović et al., 2000).

The use of MINAZEL at a level of 0.2% in broilers diets had a positive impact on reducing mortality, achieving higher body weights and improving FCR (Palić et al., 1990; 1991; Radović et al., 1999; 2003; 2004).

Bočarov-Stančić et al. (2000) added zeolites into meal feeds for broilers and found enhanced growth of 1.7-2.6%, and better FCR by 5.9-6.4% in the supplemented compared to the control group.

Zeolite (clinoptilolite) supplemented

at levels of 1.2% and 4% in feed had a positive effect on weight gain, final body weight

and FCR in broilers, with the best performances seen in those receiving the 2% zeolite

feed.

Adding MINAZEL at a level of 0.5% had a positive impact on body weight and growth of broilers and prevented the deposition of aflatoxin B1 in organs (Sinovec and Resanovic, 2005; Resanović and Sinovec, 2006).

Adding MINAZEL at a level of 0.5% had a positive impact on body weight and growth of broilers and prevented the deposition of aflatoxin B1 in organs (Sinovec and Resanovic, 2005; Resanović and Sinovec, 2006).

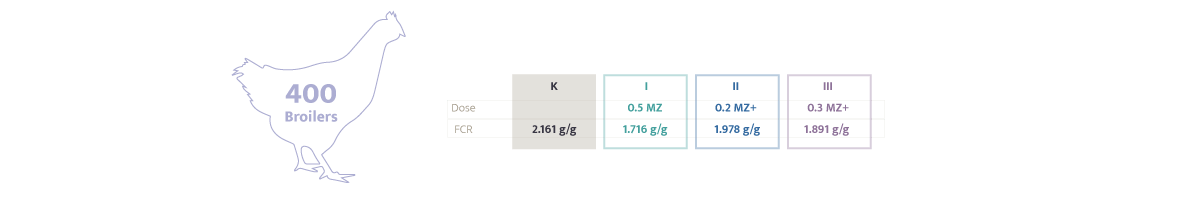

Studies

The effects of different types and levels of mineral adsorbents (MINAZEL and ‘Min-a-Zel

Plus’ (MZ+)) on production and slaughter characteristics of broilers at 42 days were

studied by Karović (2009), Karović et al. (2010) and Radovic et al. (2010a; 2010c).

During the fattening stage, different zeolites at different levels were used and compared to a negative control; MINAZEL at 0.5%; MINAZEL PLUS at 0.2% and MINAZEL PLUS at 0.3% inclusion.

The authors

concluded that the maximum weight gain was seen at 0.5% inclusion, and the percentage

of inedible products was highest in the 0.2% group.

Radović et al. (2010a) examined the

impact of different levels of mineral adsorbents (MINAZEL and MINAZEL’) added to broiler feed on

production.

A trial was conducted with 400 broilers from one day old, of Cobb 500

breed, divided into four experimental groups. The control group (K) and experimental

groups (I, II and III) were fed a complete feed of the same composition, with different

levels of added mineral adsorbent (0.5, 0.2 and 0.3% respectively).

The authors showed that 0.5% supplementation gave the best feed conversion (1.716 g/g), followed by 0.3% (1.891 g/g) and 0.2% (1.978 g/g), with the poorest seen for the control group (2.161 g/g). In addition, the highest average body weights, average daily gains, and best FCR was observed for the 0.5% group.

The authors concluded that broilers fed complete feeds with 0.5% clinoptilolite gave better results, and that the differences between the mid values were statistically significant (P< 0.05).

The authors showed that 0.5% supplementation gave the best feed conversion (1.716 g/g), followed by 0.3% (1.891 g/g) and 0.2% (1.978 g/g), with the poorest seen for the control group (2.161 g/g). In addition, the highest average body weights, average daily gains, and best FCR was observed for the 0.5% group.

The authors concluded that broilers fed complete feeds with 0.5% clinoptilolite gave better results, and that the differences between the mid values were statistically significant (P< 0.05).

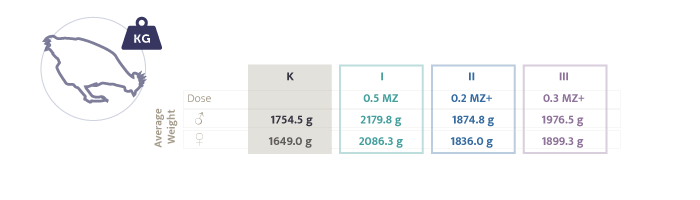

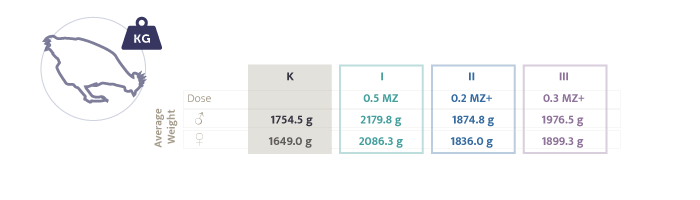

Similar studies were conducted by Radović et al. (2009; 2010b) who explored the

influence of the addition of the mineral adsorbents MINAZEL and MINAZEL PLUS to feed on the yield of

broiler chickens separated by gender.

The research was conducted on 400 Cobb 500 broilers, divided into four treatment groups, until they were 42 days of age.

Dietary treatments included a control (0%), 0.5% MINAZEL, 0.2% MINAZEL PLUS and 0.3% MINAZEL PLUS.

- The highest mortality was seen in the control group

- The lowest mortality: in the experimental group with the addition of 0.3% ‘ MINAZEL PLUS.

Average body weight

- The highest average body weight of chickens were in the 0.5% group (♂ 2179.8 g, ♀ 2086.3 g).

- Weight gain of chickens fed 0.3% MINAZEL PLUS ranged between 1976.5 g (♂) and 1899.3 g (♀).

- The average weight of chickens fed 0.2% MINAZEL PLUS was 1874.8 g (♂) and 1836.0 g (♀).

- The chickens in the control group had the lowest weights (♂ 1754.5 g, ♀ 1649.0).

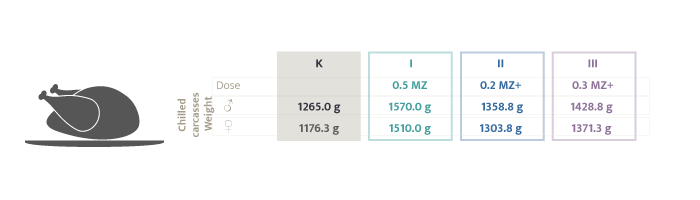

Weight of chilled carcasses

- Best total weight of chilled carcasses was found in the 0.5% supplemented group of chickens (♂ 1570.0 g, ♀ 1510.0 g)

- Followed by 0.3% (♂ 1428.8 g, ♀ 1371.3 g),

- 0.2% (♂ - 1358.8 g, ♀ - 1303.8 g)

- Control (♂ - 1265.0 g, ♀ - 1176.3)

The lowest yield (71%) was found in female broilers in the 0.2% group, while

the highest value of 72.5% was in the same treatment of male broilers.

Palić et al. (1990) conducted a trial using one-day old chickens, divided into three groups of 50 animals.

One experimental group received T-2 toxin at a level of 1 mg/kg body weight directly into the crop.

The other groups received the same treatment, but with the addition of 0.2% MINAZEL into the feed.

One experimental group received T-2 toxin at a level of 1 mg/kg body weight directly into the crop.

The other groups received the same treatment, but with the addition of 0.2% MINAZEL into the feed.

The group that received the MINAZEL achieved the highest average body weight (899 g) compared to the chicks that did not receive the mycotoxin adsorbent (805 g).

In a further experiment with broilers, (Palić et al., 1991)

zeolite supplement in doses of 0, 0.2, 0.5, and 1.0% in feed contaminated with 5.0 and

5.4 mg/kg zearalenone.

It was determined that 0.2% MINAZEL gave the best results, showing the lowest mortality, highest weight and lowest average feed consumption per kg gain.

In a study with 100 broilers divided into four groups of 25 animals, a complete diet

either without zeolite (control) or with the addition of 0.2%, 0.5% and 1% zeolite.

Rajić et al. (1992) found that:

Rajić et al. (1992) found that:

- The average weight of the experimental groups, compared to the control, on the 35th and 40th day of age were significantly higher (P< 0.001).

- FCR, relative to the control group, was 3.4% lower for the 0.2% group, 3.66% for the 0.5% group and 3.70% for the 0.1% group.

Based on these results, the authors concluded that the addition of zeolite to feed for chickens had a positive impact on body weight and feed conversion.

In a dose response trial for zeolite (0, 2.5 and 5%) Rajić et al. (1992) found that

chickens fed 2.5% supplemented feed had 9% higher body weights and 4-8% improved

feed conversion.

Kelemen and Bogaromy (1983) fed broiler chickens with a feed

containing 3% and 10% zeolite.

The 3% diet had less influence on body weight than that supplemented with 10% in the final (grower) stage of feeding. Average chicken body weight on day 49 was 3.5% to 4% less in the control chickens group.

The 3% diet had less influence on body weight than that supplemented with 10% in the final (grower) stage of feeding. Average chicken body weight on day 49 was 3.5% to 4% less in the control chickens group.

In addition, Duff et

al. (1987) found that mycotoxins that cause inhibition of growth can also cause a

reduction in bone strength.

It is considered that the presence of even minimal

amounts of OTA (> 0.5 ppm) can cause a negative effect on the broiler performance.

These negative effects are already evident at the end of the first week of age, when fed contaminated feed, and chicks then lag behind in growth, which is dose dependent, but which is more pronounced in males.

These negative effects are already evident at the end of the first week of age, when fed contaminated feed, and chicks then lag behind in growth, which is dose dependent, but which is more pronounced in males.

Exposure to contaminated feed without supplementation with a mineral adsorbent for longer periods causes a significant decrease in body weight (~ 12%) and increased feed conversion ratio.

The results for average daily gains in broilers show that mycotoxins cause significantly negative effects on this parameter. Ayed et al. (1991) found significantly lower daily weight gains in broilers fed contaminated feeds without adsorbent supplementation.

Valdivia et al. (1993) found that the addition of 5% zeolite stimulated the growth of

broilers fattened to 49 days.

Similarly, Talanov et al. (1994) noted that 3% of zeolite or

3% zeolite plus 0.04% methionine, significantly (P< 0.05) affected daily gain compared to

the control group.

Similar studies with 5% zeolite supplementation in broiler feed was

carried out by Karelin (1985) who found that the average chicken gains were 1593 g for

the supplemented group versus 1528 g for the control group. The percent of live chickens

was 91.1 and 96.5 respectively.

Sukan et al. (1994) added 1% of zeolite to broiler feed

which was not contaminated with mycotoxins. Results showed that body weight of

chicks and daily gain were increased with zeolite, but also caused higher (poorer)

feed conversion.

Similar tests were conducted by Dobeic and Amon (1994), where

clinoptilolite was added in quantities of 1, 2, 4 and 6% to feed. Clinoptilolite at 1, 2

and 4% resulted in increasing gain, higher final body weights and better feed conversion.

Clinoptilolite increased the number of erythrocytes in the blood, while the 6% inclusion

level led to decreased moisture in the faeces. Furthermore, the addition of 1% zeolite in

feed reduced aflatoxin B1 residues by 72%, although 2% zeolite gave the same levels of

residues as the control group (no aflatoxins), with gain improvements of 1.7-2.6%, and

better feed utilisation of 5.9-6.4%.

The use of zeolites (clinoptilolite) in various amounts (1, 2, 4 and 6%) showed that feeding 1, 2 and 4% had a positive effect on body weight gain and final weight of broiler chickens.

The highest body weight and feed conversion efficiency were in the group of broilers fed 2% zeolite in the ration.

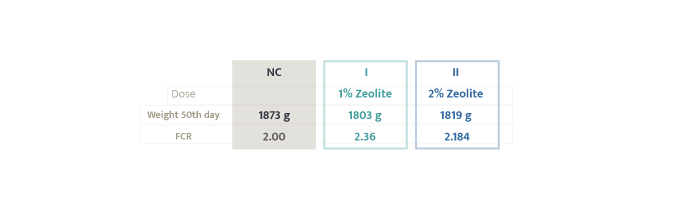

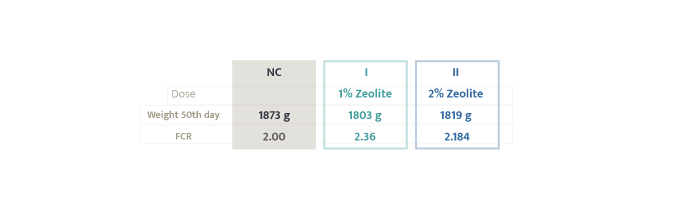

Závodský et al. (1985) fed males and females with 1% and 2% of zeolite in feed.

-

On

the 50th day of feeding, the body weight was 1803 g and 1819 g (with 1% or 2% of

zeolite respectively).

The body weight of chickens fed the negative control was 1873 g. - Feed conversion in which the zeolite was added was 2.36 and 2.184, and without zeolite it was 2.00.

Lon-Wo et al. (1987) fattened chickens with feed containing 5% of zeolite

for a period of eight weeks.

They determined that the fattening production results at the

beginning of the trial in both groups of chickens were very similar, but at the end of trial

period, feed efficiency was better and mortality lower for the broilers which received

zeolite (P< 0.05).

Addition of 5% zeolite in the finishing feed for chickens gave

significant improvements in feed conversion (P< 0.05).

In a second experiment, 20

geese aged 7-21 days old were fed a ration contaminated with aflatoxin B1, B2 and

G1 concentrate, with and without zeolite. Zeolite addition improved conversion and

carcass yield.

Application of zeolite in feed to prevent poultry mycotoxicosis has been shown to be effective (Sinovec et al., 2002; Radović and Bogosavljević-Bosković, 2006) both in experimental (Resanović et al., 2004), and practical conditions (Palić et al., 1991).

- Adding zeolite in feed contaminated with different mycotoxins reduces pathomorphological alterations in target organs (Nedeljković-Trailović et al., 2001; 2004).

- In addition, significant reductions in the presence of residues in edible tissues of broilers have been noted (Sinovec et al., 2002).

- But it should be stated that the efficiency of zeolite depends on the application and form in which it is used (Radović et al., 2000; Resanović et al., 2004).

Conclusions

It is assumed that different levels of mineral adsorbents added to the feed of broiler chickens have different and unequal effects on consumption and feed conversion, body weight gain, final body weights, carcass traits and meat quality as well as the health status of chickens in accordance with duration and economic performance.Tica et al. (2010) also demonstrated the impact of zeolites on the economic performance of growing broiler chickens exposed to mycotoxins.

The use of mineral adsorbents in feeds and premixes can provide a solution to mycotoxicosis, showing better productive performance and economic returns to growers.

However, in Serbia, the full benefits of the use of mineral absorbents can only be seen with the readiness of customers to purchase poultry meat products according to their quality.

Increasing needs of consumers for improved food safety and quality impose constant problems in producing suitable and acceptable poultry meat and eggs. Mycotoxin contamination of animal feed and resulting residues in meat and eggs are therefore an important consideration in poultry production.

Because mineral adsorbents are broadly used in poultry diets, they contribute greatly in improving the quality of feedstuffs, productive performance, meat quality and carcass yield.

For egg production, adsorbents can help increase egg production in laying hens, reduce mortality, improve feed conversion and prevent the occurrence of various pathological changes.

Acknowledgements The authors are grateful to the Ministry of Education and Science of Republic of Serbia, for sponsoring part of the study in project № TR – 31033 and TR – 20066.

References

ADAMOVIĆ, M., TOMAŠEVIĆ-ČANOVIĆ, M., MILOŠEVIĆ, S., DAKOVIĆ, A. and LEMIĆ, J. (2003)

The contribution of mineral adsorbents improving production and reproductive traits to general health and

quality of animal products. Biotechnology in Animal Husbandry 19(5-6): 383–395.

AYED, M., DAFALLA, R., YAGI, I. and SEI, A. (1991) Effect of ochratoxin A on Lohman type chicks. Vet.

Hum. Toxicology 33: 557-560.

BOČAROV-STANČIĆ, A., MILOVAC, M. and GOLOŠIN, B. (2000) Detection of mycotoxins in cereals

and animal feed. Proceedings of the Conference ITNMS, Belgrade, pp. 74-77.

BOYER, J. (2000) Zeolite in animal nutrition. Undergraduete Seminar, http://animsci.agrenv.mcgill.ca/courses/

ugradsem/00_01/Boyer_Sci.html.

DIXON, J.B. and WEED, S.B. (1989) Zeolites in soils. Minerals in Soils Environments. Soil Science Society

of America, pp 873-906 (Wisconsin, Academic Press).

DOBEIC, M. and AMON, M. (1994) Influence of local clinoptilolite in the broiler chicken production.

Proceeding of the 8 international Congress of Animal Hygiene, St. Paul. Minesota, USA, pp. 71-74.

DUFF, S., BURNS, R. and DWIEVEDI, P. (1987) Skeletal changes in broiler chicks and turkey poults fed

diets containing ochratoxin A. Research in Veterinary Science 43: 301-307.

FILIPOVIĆ, S., FILIPOVIĆ, N. and IVIĆ, M. (1993) Testing homogeneity of powder mixtures. Žitohleb 20:

131-134.JAJIĆ, I., JURIĆ, V., GLAMOČIĆ, D. and KRSTOVIĆ, S. (2010) Occurrence of deoxynivalenol and

zearalenone in maize. Contemporary agriculture 59(3-4): 227-233.

KARELINA, O. (1985) Zeolites fog feeding broilers. Ptitosevodstvo 9: 26.

KAROVIĆ, D. (2009) The mineral adsorbents effect on production and quality meat broilers fattening. Msc.

Thesis, University of Kragujevac.

KAROVIĆ, D., RADOVIĆ, V., OKANOVIĆ, Đ., DŽINIĆ, N., IKONIĆ, P., TASIĆ, T. and GUBIĆ, J.

(2010) The influence of additives in food of mycotoxins adsorbents for broilers on the quality of by-products.

Proceedings of the XV Conference on Biotechnology, Čačak, 15(17): 511-516.

KELEMEN, G.B.K. and BOGAROMY, Z. (1983) Utilization of zeovite in the feeding of chickens. A zeovite

felhasznalasa pecsenyecsirken takarmanyozasaban. Mosonmagyarovary Mesogazdagtudomanyi Kar

Kozlemenyei, 25, 1/10, 79-94.

LON-WO, E., PEREZ, F. and GONZALES, J.L. (1987) Inclusion of 5% zeolite (clinoptilolite) in diets for

fettening chickens under commercial conditions. Cuban Journal of Agriculture 21(2): 165-169.

NEDELJKOVIĆ-TRAILOVIĆ, J., JOVANOVIĆ, N. and SINOVEC, Z. (2004) Effect of exposure time and

dietary ochratoxin A (OTA) level on broiler performance. Acta Veterinaria 54: 419-426.

NEDELJKOVIĆ-TRAILOVIĆ, J., ŠEFER, D., SINOVEC, S., ZUROVAC-KUZMAN, O. and

SINOVEC, Z. (2001) Prevention of ochratoxicoses in broilers using modified clinoptilolite. XII

International congress WVPA, Cairo, pp. 377.

OŽEGOVIĆ, L. (1983) Micotoxicosis of poultry. Veterinaria 33: 393-410.

PALIĆ, T., PETROVIĆ, R., STANOJLOVIĆ, M. and JOVANOVIĆ, Dj. (1991) Applicability of Mycosel

of poisoning chickens T-2 mycotoxin. Proceedings of Conference on „Poultry days’, Zlatibor, pp. 117-119.

PALIĆ, T., VUKIĆEVIĆ, O. and RAJIĆ, I. (1990) Possibility of application of zeolites in modern livestock

production. Veterinary Bulletin 44(10): 879-887.

RADOVIĆ, V. (1997) The influence of zeolite in the diet of laying hens Isabrown SSL on production and egg

quality. Msc. Thesis, University of Kragujevac.

RADOVIĆ, V. and BOGOSAVLJEVIĆ-BOŠKOVIĆ, S. (2006) Application of natural zeolite in poultry

nutrition. Natural mineral resources and possibilities of their use in agricultural production and food industry.

Proceedings of the Association of Agricultural Engineers and Geoinstitut, Belgrade, pp. 121-128.

RADOVIĆ, V., FILIPOVIĆ, S., OKANOVIĆ, Đ., KAROVIĆ, D. and KORMANJOŠ, Š. (2010a) The

effects of mineral adsorbents on feed conversion in fattening of broilers. Proceedings of the XV Conference

on biotechnology, Čačak, 15(17): 603-608.

RADOVIĆ, V., FILIPOVIĆ, S., OKANOVIĆ, Đ., RISTIĆ, M., KORMANJOŠ, Š. and KAROVIĆ, D.

(2010b) Effect of mineral adsorbents added to the food the broiler carcass yield. International 55th Meat

Industry Conference, Tara, Book of Abstract, pp. 158-159.

RADOVIĆ, V., KAROVIĆ, D., OKANOVIĆ, Đ., FILIPOVIĆ, S., GUBIĆ, J., TASIĆ, T. and IKONIĆ, P.

(2010c) The influence of mineral adsorbents in addition to the results of fattening food of broilers. I

Workshop, XIII International Symposium on Technology Feed for Animals, Novi Sad, pp. 268-277.

RADOVIĆ, V., KAROVIĆ, D., OKANOVIĆ, Đ., FILIPOVIĆ, S. and KORMANJOŠ, Š. (2009) Effect of

mineral adsorbents added to food production results in a broiler. Meat Technology 50(5-6): 271-275.

RADOVIĆ, V., RAJIĆ, I. and BOGOSAVLJEVIĆ-BOŠKOVIĆ, S. (2004) Min–a–Zel Plus eating turkeys

for fattening, the impact on production traits. Biotechnology in Animal Husbandry (spec.issue) 20(5-6): 259-

263.

RADOVIĆ, V., RAJIĆ, I. and RADOVANOVIĆ, T. (1999) The influence of zeolite added to the feed for

laying hens on the weight and thickness of shell eggs. Acta periodica tehnologica 31: 397-402.

RADOVIĆ, V., RAJIĆ, I. and RADOVANOVIĆ, T. (2000) The influence of zeolite added to the feed

mixture to the number of hens eggs of Hough units. Scientific Symposium on Agriculture of the Republic of

Serbian with International Participation, Book of Abstract, Teslić, pp. 113.

RADOVIĆ, V., RAJIĆ, I., STANIĆ, D. and NADAŽDIN, M. (2003) The effect of different phosphorus

sources on growth and body weight of chickens for fattening. Biotechnology in Animal Husbandry 19(3–4):

43–48.

RAJIĆ, I., KONJEVIĆ, M. and VLAHOVIĆ, M. (1992) The influence of zeolite added to the contaminated

feed mixtures zearalenone (F-2) on growth and feed conversion of broilers. Biotechnology in Animal

Husbandry (spec.issue) 8(5-6): 191-194.

RAJIĆ, I. and OŽEGOVIĆ, L. (1990) The influence of dance on the quality of corn and proposed measures

for prevention and rehabilitation. Krmiva 22(10): 214-219.

RESANOVIĆ, R. and SINOVEC, Z. (2006) Effects of broiler limited feeding by aflatoxin contaminated feed

on performances. 28 Mycotoxin Workshops, Bydgoszcz, pp. 56.

RESANOVIĆ, R., SINOVEC, S. and SINOVEC, Z. (2004) Effect on aflatoxin B1 tissue residues by addition

of modified clinoptilolite to aflatoxin B1 contaminated broiler diets. XIII International congres WPA,

Florence, pp. 152-158.

SEMMENS, M.J. (1983) Cation-exchange properties of natural zeolites, in: POND, W.G. & MUMPTON, F.A.

(Eds) Zeo Agriculture: Use of Natural Zeolites in Agriculture and Aquaculture, pp. 45-53 (Westview Press,

Boulder, Colorado).

SINOVEC, Z. and RESANOVIĆ, R. (2005) Prevention and control of mycotoxicosis by using modified

clinoptilolite. Proceedings of the Serbian Heritage Natural Sciences, Belgrade, 108: 147-155.

SINOVEC, S., RESANOVIĆ, R., NEDELJKOVIĆ-TRAILOVIĆ, J., ŠEFER, D. and SINOVEC, Z.

(2002) Modified clinoptilolite as remedy for prevention of aspergillotoxicoses in poultry. 27th World

Veterinary Congress, Tunis, pp. 12-13.

SUKAN, S., ERKEK, R. and ONGEN-BAYASAL, G. (1994) Effects of enzyme and zeolite supplementation

to broiler diets: Civciv yjemi katki mmaddesi olarak takli konsantrasyonlarda enzim ve zeolit kutlanimi.

Turkish Journal of Agriculturre and Forestry 18 (2): 141-144.

ŠEFER, D., NEDELJKOVIĆ-TRAILOVIĆ, J., JOVANOVIĆ, N. and SINOVEC Z. (1997) Influence of T-

2 toxin on performances and health status on broilers. ESVCN Conference, pp. 78.

TALANOV, G.A., CHUPALKHINA, O.K., BRICHKO, N.V., USTENKO, V.V. and SKVORTESOV, F.F.

(1994) Effect of zeolite and its products on natural resitance and productivity in finishing chickens and cattle.

Problemy Vetrinarnoi Sanitari i Ekoligii 94: 15-20.

TICA, N., OKANOVIĆ, Đ., ZEKIĆ, V., KAROVIĆ, D. and MILIĆ, D. (2010) The influence of the use of

food with the addition of mineral adsorbents on economic performance in fattening broilers. 21st Symposium

on Livestock, veterinary medicine and economics in rural development and production of safe food, Belgrade,

Book of Abstract, pp. 190.

VALDIVIE, M., ELIAS, A. and GONZALEZ, L.M. (1993) Saccharina in rations for broilers with zeolite,

sugar and torula yeast. Cuban Jouranl of Agricultural Science 27(2): 187-191.

ZAVODSKY, G., SPILITEK, M., KLECKER, S. and VODA, M. (1985) Zeoilite in mixed feeds for broilers.

Zeolity v krmivarske praxi. Krmivarstvi a Služby 21(4): 78-80.

342

Micotoxicosis prevention

Micotoxicosis prevention