Dr. Rui Alexandre Gonçalves

Aquaculture and Mycotoxin Expert

Aquaculture Business Developer – Lucta S.A.

Innovation Division – Feed Additives

UAB Research Park, Bellaterra, Barcelona, Spain

The awareness of mycotoxin-related issues in the aquaculture industry has been increasing, accentuated by the replacement of marine ingredients (Gonçalves et al., 2018; Tacon et al., 2011).

| Traditionally, the use of minor amounts of plant feedstuffs led to a general perception that mycotoxins were not a relevant issue in aquaculture and that the majority of mycotoxin-related issues would only arise due to poor storage conditions, i.e., aflatoxin contamination, but this is not entirely true. |

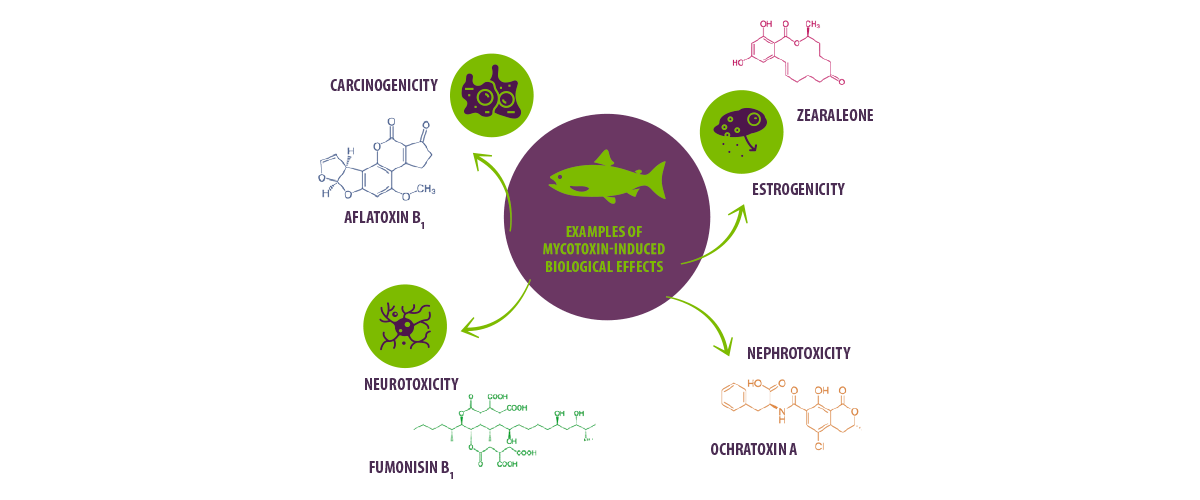

Mycotoxins are secondary metabolites produced by some molds (Hussein and Brasel, 2001). They are commonly reported to appear in agricultural commodities (pre-and/ or post-harvest), including finished feeds.

Chemically, mycotoxins have low molecular weight, displaying a wide range of structures (Mallmann and Dilkin, 2007). This variability is responsible for the diverse biological effects produced by mycotoxins.

Despite being identified as categorically undesirable for most animal species, the occurrence of mycotoxins, at least in field conditions, is not completely preventable even when using good manufacturing practices. Despite being identified as categorically undesirable for most animal species, the occurrence of mycotoxins, at least in field conditions, is not completely preventable even when using good manufacturing practices. |

As mycotoxins are mainly found in agricultural commodities, the tendency to replace animal-derived proteins, such as fish meal, with plant protein sources has increased the risk of mycotoxin contamination in aquaculture feeds.

Generally, plant-based meals are known for their natural profile of anti-nutritional factors (ANF’s), such as cyanogens, saponins, tannins, etc., that are harmful to fish and shrimp (Krogdahl et al., 2010).

⇰ Although there are processes that aid in the removal or inactivation of many of these ANF’s, the same does not apply to mycotoxins, as they are highly stable when subjected to processing conditions (e.g., high temperature and pressure) (Cheli et al., 2013).

Not all plant meals are the same!

The difficulty in understanding the risk of mycotoxin contamination in aquaculture finished feeds is related to the diversity of aquaculture species. For most species, the selection of plant meals depends on a combination of factors (Davis y Sookying, 2009; Gatlin et al., 2007; Krogdahl et al., 2010):

- ⇰ Local market availability.

- ⇰ Cost.

- ⇰ The protein meal’s nutritional profile (anti-nutritional factor content and levels).

However, depending on the species and production region, evaluating mycotoxin contamination may not be a common practice in the aquaculture industry, so it becomes difficult to understand the contamination risk of certain plant commodities, especially the ones used locally.

Moreover, climate change and world commodities trade also contribute to the difficulty in predicting the risk of mycotoxin contamination in aquaculture finished feeds.

In some countries, mycotoxin contamination is considered a strictly seasonal issue. However, the increasing globalization of trade and incorporation of imported raw materials in aquafeeds exposes the industry to the risk of mycotoxins that may not be common for the region.

In some countries, mycotoxin contamination is considered a strictly seasonal issue. However, the increasing globalization of trade and incorporation of imported raw materials in aquafeeds exposes the industry to the risk of mycotoxins that may not be common for the region.

When plant meals get too expensive

Micotoxicosis prevention

Micotoxicosis prevention